-

With 3D printing, a new innovation can be quickly, cost-effectively, and high-quality ready for sale.

With 3D printing, a new innovation can be quickly, cost-effectively, and high-quality ready for sale.

3D Printing

Posted by

Juha Mäki

Posted at

Embedded Systems

Posted on

Mar 1, 2023

The collaboration between 3D Formtech, Nottas, and LINK Design And Development Oy began in December 2022 when Nottas needed a manufacturer for the casing around the electronics of the eFeeler controller. We reviewed the customer's needs, the manufacturability of the part, and the estimate of the optimized production batch. We first produced a batch of 10 models based on the 3D designs created by Ilkka Husgafvelin from LINK Design And Development Oy. One of the benefits of industrial-level 3D printing is that it allows for agile transition from design to production, and quick changes can be made based on the first prototypes without significant costs or initial investments.

Nottas had previous experience with 3D printing for prototype production, but approached small-scale production with an open mind. 'We wanted to avoid mold costs and ended up in discussions with 3D Formtech. I started to see how industrial-level 3D printing would suit as a manufacturing method for casings, and I have been very satisfied!' describes Juha Mäki, Chief Technology Officer at Nottas Oy.

Faster design and clear cost savings with 3D printing.

Husgafvelin, who was responsible for the design, mechanical engineering, and styling of the parts, cites the main benefits of industrial-level 3D printing as rapid design and production, low initial investments, and design freedom. 'Technologies have advanced a lot in the past few years! If the same part had been manufactured by injection molding, it would have required more adherence to mold-related restrictions and principles in the design. Additionally, making the mold would have cost thousands of euros, and the product manufacturing process would have taken about a year.' By manufacturing the casing around the electronics with 3D printing, it took only 1.5 months, and Nottas has been able to pre-market and sell the new product quickly, efficiently, and without large initial investments and big inventories.

"This is a good example of how a company doesn't need to tie up large amounts of money in molds or produce large batches for inventory. 3D printing offers flexibility because parts can be produced quickly and agilely as orders come in. This way, the company can quickly enter the market with a new innovation, and the customer doesn't have to wait for half a year," summarizes Lasse-Matti Nieminen, sales manager at 3D Formtech.

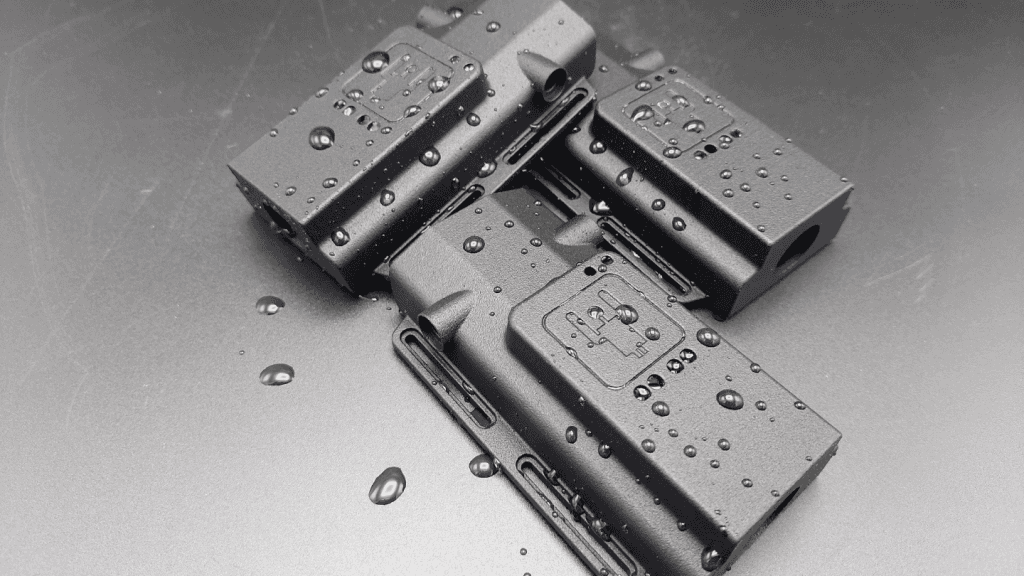

The material chosen for the parts was PA2200, which is well-suited for various plastic prints. It is strong and withstands mechanical stress and chemicals well. The material has a plastic-like appearance and allows for precise details in the product. At 3D Formtech, the finishing of the parts always includes ensuring surface quality by blasting them into shape. The parts were post-processed by dyeing them black, and additionally, a water- and oil-repellent micro-coating was applied to the exterior surface to keep the part clean and easy to maintain.

Collaboration with 3D Formtech receives praise.

Collaboration with 3D Formtech receives praise from both Mäki and Husgafvelin. 'The company's website already gave a good impression, and the service has been very good and professional! They have been enthusiastic about our product, and the quality has been better than I expected,' summarizes Mäki.

Husgafvelin is also on the same page. 'The collaboration has been very smooth with both Nottas and 3D Formtech. Everything has worked very well, even though we haven't met face-to-face, but have been in contact via phone and Teams.' He wants to send special greetings to companies and designers who are still considering utilizing 3D printing: 'Not everyone yet knows how good an option 3D printing is for small-scale production as well. When tool costs are eliminated and all the constraints of injection molding don't need to be considered, the design of parts becomes significantly more straightforward and faster.

3D Formtech is also pleased with the smooth and successful collaboration. This is a very timely innovation that was brought to market very cost-effectively, quickly, and agilely by utilizing industrial-level 3D printing, high-quality materials, good design, and professional post-processing. The eFeeler controller is available in well-stocked online stores and department stores, and deliveries will begin on March 17, 2023.